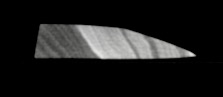

The Weaving sword (or “batten,” “sword,” or “beater”) is single edge shaped wooden stick used to pack down weft threads and in doing so separate and increase the size of the shed. They average three feet long and 2 ¼ inches wide, but must be at least several inches longer than the total width of the warp so they extend outside of the warp during weaving. There is a subtle curvature to the top face when the sword lies flat.

Weaving Swords are traditionally made from very hard woods, which is essential for having a sword of sufficient weight and maintaining a sufficiently sharp edge. Specifically, they are crafted of ironwood, the Casuarina litorea L, known locally as weighu.

While swords can be made of store-bought hardwoods, such as oak, these tend to lack the weight and density weavers require. Oak sold at home improvement stores tends to be red oak (Quercus rubra).

The only woods commonly found in North America which approach the hardness of ironwood are Black Ironwood (Krugiodendron ferreum), Desert Ironwood (Olneya tesota) and Mountain Mahogany (Cercocarpus spp) but these are either cost or shape prohibitive.

Remathau in the mainland US seeking a weaving sword should look to friends and relatives back home to send them a hapop or contact Habele for help. Alternatively, they may try to fabricate an ersatz sword using oak, but will need to use Live Oak, also called Southern Live Oak (Quercus virginiana) to ensure a sufficient density.

With construction complete, continue to a list of thread vendors in the US.